Susan Cox, CEO and Founder of LogoJET Inc. actively engages with various industry associations, including PRINTING United and the International Sign Association. She is a member of the Academy of Screen and Digital Print Technologies who recognizes individuals who have contributed to the technical growth and advancement of the printing industry. She is a frequent speaker at industry trade shows and entrepreneurial gatherings. Susan has dedicated multiple years to the Award and Personalization Association (APA), serving on its Board of Directors and Communications Committee, as well as volunteering on the Tradeshow Committee for six successive years. In addition, she contributes her leadership skills to the board of the International Trade Development Group for Louisiana. Susan regularly shares her extensive experience in team development and her passion for guiding the next generation of entrepreneurs. A Toronto native, Susan relocated LogoJET to Louisiana 14 years ago. Her core business philosophy centers around fostering long-term customer relationships and aligning company strategies with client-centric success.

Key Concepts in UV Printing Adhesion

Primers and Adhesion Promoters

Applying an adhesion promoter can significantly improve ink adhesion, especially on difficult substrates like plastics. These products create a bondable surface, enhancing the ink's ability to stick. This process is best applied manually by applying the liquid pretreatment to a lint-free microfiber cloth and applying to printable area before printing. This process is fast and dries within a few seconds and in some cases can be applied in advance up to 24 hours before printing if the applied area is not handled with fingerprints.

Always be sure to follow the manufacturers’ application suggestions and guidelines. There is no single best adhesion promoter, as they are each designed for specific substrates and applications. Also, pay close attention to storing instructions and expiry dates, as some have a 6-12 month shelf life.

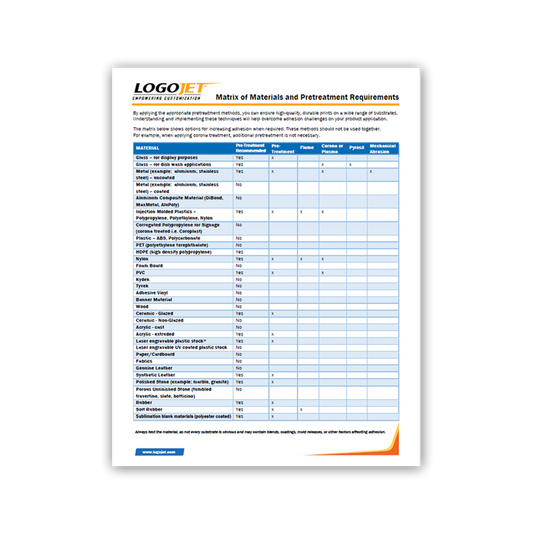

Master UV Printing Adhesion: Get Your Free Complete Guide!

Download the Complete Adhesion Materials and Supplies Guide

Includes a matrix that outlines various materials commonly used in UV printing and indicates whether pretreatment is required for optimal adhesion.